Hebei Hengcheng Conveying Equipment Co., Ltd.,Contact Now Get 20-30% Off

Description

Uses

Due to site limitations or the need to lift materials at a large inclination angle, in order to prevent the scattering of conveyed materials, the sidewall conveyor belt must be able to withstand very high stresses and repeated bending that occur during high-volume, steep-angle conveying. High-quality, very low elongation polyester fabrics are used to provide higher stiffness values. This product is suitable for conveying materials under large inclination angles (0°-90°).

Features

• Conveying materials can achieve a large inclination angle up to 90°

• Large conveying capacity, materials will not scatter. Conveying can transition from horizontal to inclined, and from inclined to horizontal angles.

Standards

| Type | Tensile Strength N/mm | Kind | Number of Carcass Layers | Cover Rubber Thickness (mm) | Weight (kg/m 2) | Minimum Roller Diameter mm |

| XE | 200 | Ordinary | 2 | 2x2 | 9.8 | 200 |

| XOE | 315 |

Ordinary Heat Resistant Flame Retardant

|

2+1 | 4x2 | 11.3 | 315 |

| 500 | 3+1 | 4x2 | 13.2 | 400 | ||

| 630 | 4+1 | 4x2 | 14.9 | 500 | ||

| 800 | 5+1 | 4x2 | 17.8 | 630 | ||

| 1000 | 6+1 | 5x3 | 22.0 | 800 | ||

| XUE | 315 | Ordinary | 2+1 | 4x3 | 12.7 | 315 |

| 500 | 3+1 | 4x3 | 14.5 | 400 | ||

| 630 | 4+1 | 4x3 | 16.3 | 500 | ||

| XDE | 315 | Ordinary | 2+2 | 4x3 | 13.7 | 315 |

| 500 | 3+2 | 4x3 | 15.5 | 400 | ||

| 630 | 4+2 | 4x3 | 17.3 | 500 |

Corrugated Sidewall

The sidewall is made of high-quality rubber.

There are also two types: pure rubber (BG) and rubber with fabric reinforcement layer (BGT)

| Conveying Occasions | Height | Sidewall Width | Bottom Width | Weight | Minimum Roller Diameter |

| mm | mm | mm | mm | mm | |

| N | 80 | 44 | 50 | 1.6 | 200 |

| 100 | 44 | 50 | 1.8 | 250 | |

| S | 120 | 66 | 75 | 3.1 | 320 |

| 160 | 66 | 75 | 4.1 | 400 | |

| 200 | 66 | 75 | 5.1 | 500 | |

| 240 | 66 | 75 | 6.1 | 550 | |

| ES | 300 | 88 | 100 | 12.0 | 700 |

| 400 | 88 | 100 | 16.0 | 900 |

Note: N-Light Load; S-Medium Load; ES-Heavy Load.

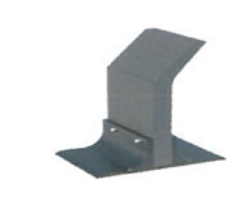

Bulkhead

The bulkhead is made of high-quality rubber and has a high elastic support function.

There are also two types: pure rubber, rubber with fabric reinforcement layer

| T |  |

Type | T75 | T110 | ||||

| Height (mm) | 75 | 110 | ||||||

| Weight (Kg/m) | 1.65 | 2.20 | ||||||

| Minimum Roller Diameter (mm) | 200 | 300 | ||||||

| TC |  |

Type | TC110 | TC140 | TC180 | TC220 | TC260 | |

| Height (mm) | 110 | 140 | 180 | 220 | 260 | |||

| Weight (Kg/m) | 2.6 | 5.5 | 7.0 | 8.0 | 10.2 | |||

| Minimum Roller Diameter (mm) | 350 | 370 | 450 | 500 | 600 | |||

| TCS |  |

Type | TCS280 | TCS360 | ||||

| Height (mm) | 280 | 360 | ||||||

| Weight (Kg/m) | 18.5 | 22.0 | ||||||

| Minimum Roller Diameter (mm) | 700 | 700 |

Cover Rubber Quality/Grade Standard Performance Parameters

| Chinese GB/T7984-2013 GB/T 32457-2015 Conveyor Belt Cover Layer Performance |

| Type | Tensile Strength (ISO37) Mpa |

Elongation at Break (ISO37) % |

Abrasion (ISO4649) mm 3 |

| H | 24 | 450 | 120 |

| D | 18 | 400 | 100 |

| L | 15 | 350 | 200 |

| German Standard DIN-22102 | ||||||

| Grade | Tensile Strength ≥Ma | Elongation at Break ≥M% | Abrasion ≥mm 3 | Bond Strength Between Fabric Layers (N/mm) | Bond Strength Between Cover and Fabric Layers (/mm) | |

| Cover Thickness 0.8~1.5mm | Cover Thickness >1.5mm | |||||

| W | 18 | 400 | 90 | ≥5 | 3.5 | 4.5 |

| X | 25 | 450 | 120 | |||

| Y | 20 | 400 | 150 | |||

| Z | 15 | 350 | 250 | |||

| British Standard BS 490 | ||||||

| Grade | Tensile Strength ≥Ma | Elongation at Break ≥M% | Abrasion ≥mm 3 | Bond Strength Between Fabric Layers (N/mm) | Bond Strength Between Cover and Fabric Layers (/mm) | |

| Cover Thickness 0.8~1.5mm | Cover Thickness >1.5mm | |||||

| M | 24 | 450 | - | ≥5.25 | 3.15 | 4.5 |

| N | 17 | 400 | - | |||

| Australian Standard AS 1332-2000 | ||||||

| Grade | Tensile Strength ≥Ma | Elongation at Break ≥M% | Abrasion ≥mm 3 | Bond Strength Between Fabric Layers (N/mm) | Bond Strength Between Cover and Fabric Layers (/mm) | |

| Cover Thickness 0.8~1.5mm | Cover Thickness >1.5mm | |||||

| A | 17 | 400 | 70 | 6 | 4 | 4.8 |

| E | 14 | 300 | - | |||

| F | 14 | 300 | - | |||

| M | 24 | 450 | 125 | |||

| N | 17 | 400 | 200 | |||

| S | 14 | 300 | 250 | |||

| S* | 12 | 300 | 250 | |||

| South African SANS 1173:2005 | ||||||

| Grade | Tensile Strength ≥Ma | Elongation at Break ≥M% | Abrasion ≥mm 3 | Bond Strength Between Fabric Layers (N/mm) | ||

| Bond Strength Between Cover and Fabric Layers (N/mm) | ||||||

| A | 18 | 400 | 90 | ≥7 | ≥5 | |

| X | 25 | 450 | 120 | |||

| M | 24 | 450 | 150 | |||

| N | 20 | 400 | 250 | |||

Specifications and Technical Parameters of Corrugated Sidewall Multi-layer Fabric Core Conveyor Belt

| Fabric Type | Fabric Structure | Fabric Model | Rubber Belt Thickness (mm/p) | Strength Series (N/mm) | Covering Glue Thickness | Width Range (mm) | ||||||

| Warp | Weft | 2 Layers | 3 Layers | 4 Layers | 5 Layers | 6 Layers | Upper Covering Layer | Lower Covering Layer | ||||

|

Nylon EP Polyester NN EE |

Nylon | Nylon | Nylon/EP Polyester/NN/EE-100 | 1.00 | 200 | 300 | 400 | 500 | 600 | 0-12 | 0-10 | 300-2500 |

| Nylon/EP Polyester/NN/EE-125 | 1.05 | 250 | 375 | 500 | 625 | 750 | ||||||

| Nylon/EP Polyester/NN/EE-150 | 1.10 | 300 | 450 | 600 | 750 | 900 | ||||||

| Nylon/EP Polyester/NN/EE-200 | 1.20 | 400 | 600 | 800 | 1000 | 1200 | ||||||

| Nylon/EP Polyester/NN/EE-250 | 1.40 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| Nylon/EP Polyester/NN/EE-300 | 1.60 | 600 | 900 | 1200 | 1500 | 1800 | ||||||

The covering performance of the tape meets the following table

| China GB/T7984-2013 GB/T 32457-2015 Tape Covering Layer Performance Tape Covering Layer Performance | |||||

| Covering Layer Level | Tensile Strength | Elongation at Break | Abrasion Loss | Change Rate of Tensile Strength and Elongation at Break After Aging | |

| Mpa | Kgf/cm2 | % | mm 3 | % | |

| H | ≥24 | ≥240 | ≥450 | ≤120 | -25~ +25 |

| D | ≥18 | 180 | ≥400 | ≤100 | -25~ +25 |

| L | ≥15 | 150 | ≥350 | ≤200 | -25~ +25 |

Product Display

|

|

|

|

|

|

Introduce

Hebei Hengcheng Conveying Equipment Co., Ltd. is a high-tech enterprise specializing in the research and development, production and sales of conveying equipment, focusing on the manufacturing of conveyor belts, conveying rollers, idlers and their matching accessories. The company takes "high quality, low cost and excellent service" as its core competitiveness and is committed to providing one-stop material handling solutions for global customers.

Customized Process

To meet diverse industry needs, our products are categorized into multiple specifications based on material handling requirements and operational environments:Standard, Heat-Resistant, Acid/Alkali-Resistant, Oil-Resistant, Cold-Resistant, and Flame-Retardant types.

Goods will be strictly tested before delivery, please check carefully after receiving the goods, if there is any problem, please contact us in time.

Online communication

Provide custom drawings

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt of goods

Successful transaction

FAQ

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

What is the minimum order quantity?

It depends on the product.

Side conveyor belt

You still doubt it? First get samples contact us!

subcategory

keyword

Related Products

No relevant data, please add background!

Immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

HENGCHENG

Conveying Equipmen

Provide One-Stop Customized Conveying System Solutions

No. 117, Xingfu District, Nanchenggezhuang Village, Shifo Town, Anguo City, Hebei Province

Fast Navigation

Leave Us a Message

Online Message